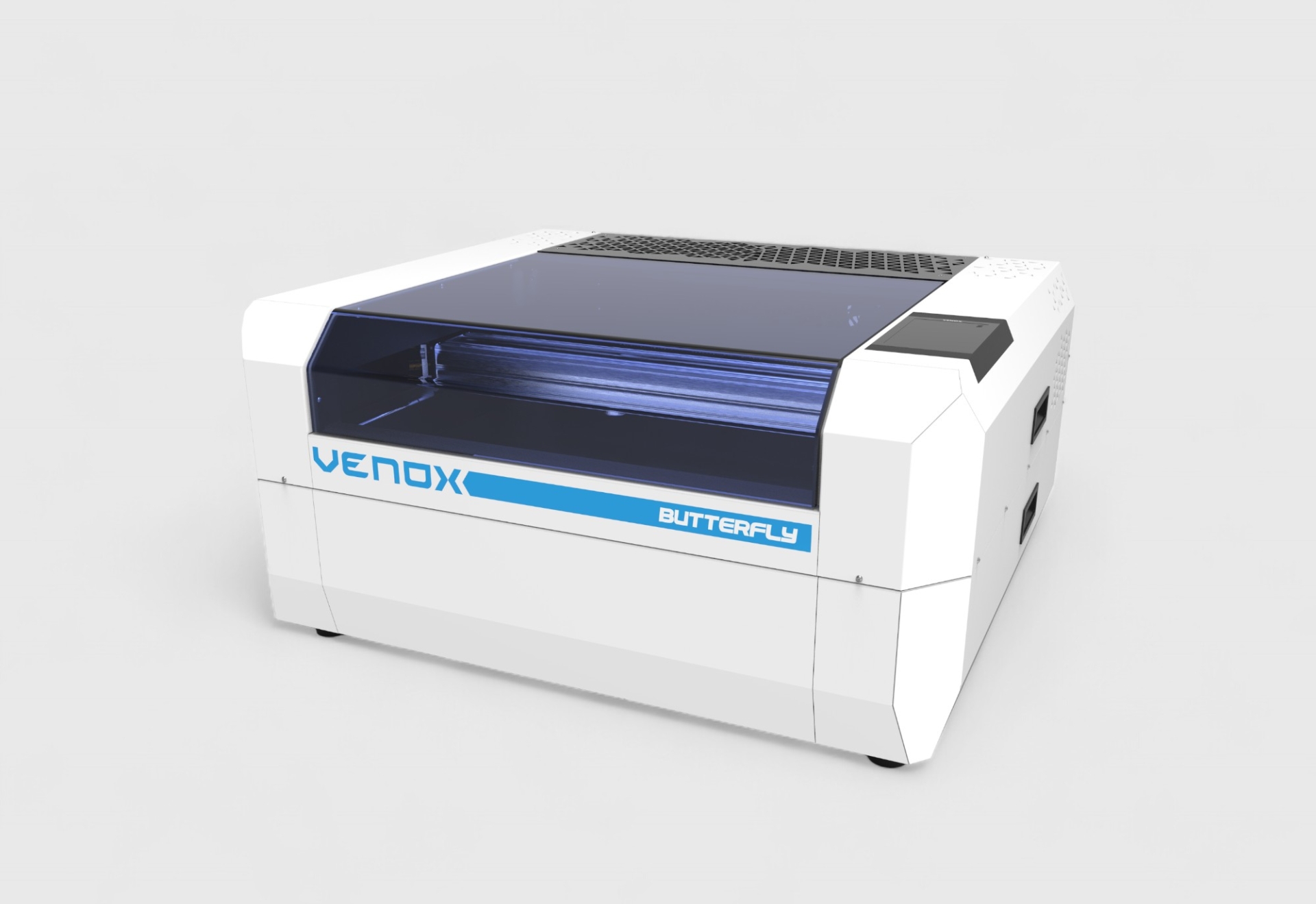

Laser Cutting and Marking Machines

These are essential pieces of equipment in modern production lines, used to process different materials with high speed and precision. Delivering clean and repeatable results on metal, wood, plastic, acrylic, fabric, and many other surfaces, these systems ensure smooth, sharp, and high-quality edges in cutting processes. Contactless laser technology reduces mechanical stress on the workpiece; by lowering the risk of deformation, it produces durable and professional outputs.

Application Areas

- Metal Processing: Cutting and marking on stainless steel, aluminum, and various metal types.

- Advertising and Design: Signage applications, acrylic panels, decorative products, and custom designs.

- Furniture and Construction: Precision cutting, patterning, and part preparation on wood panels.

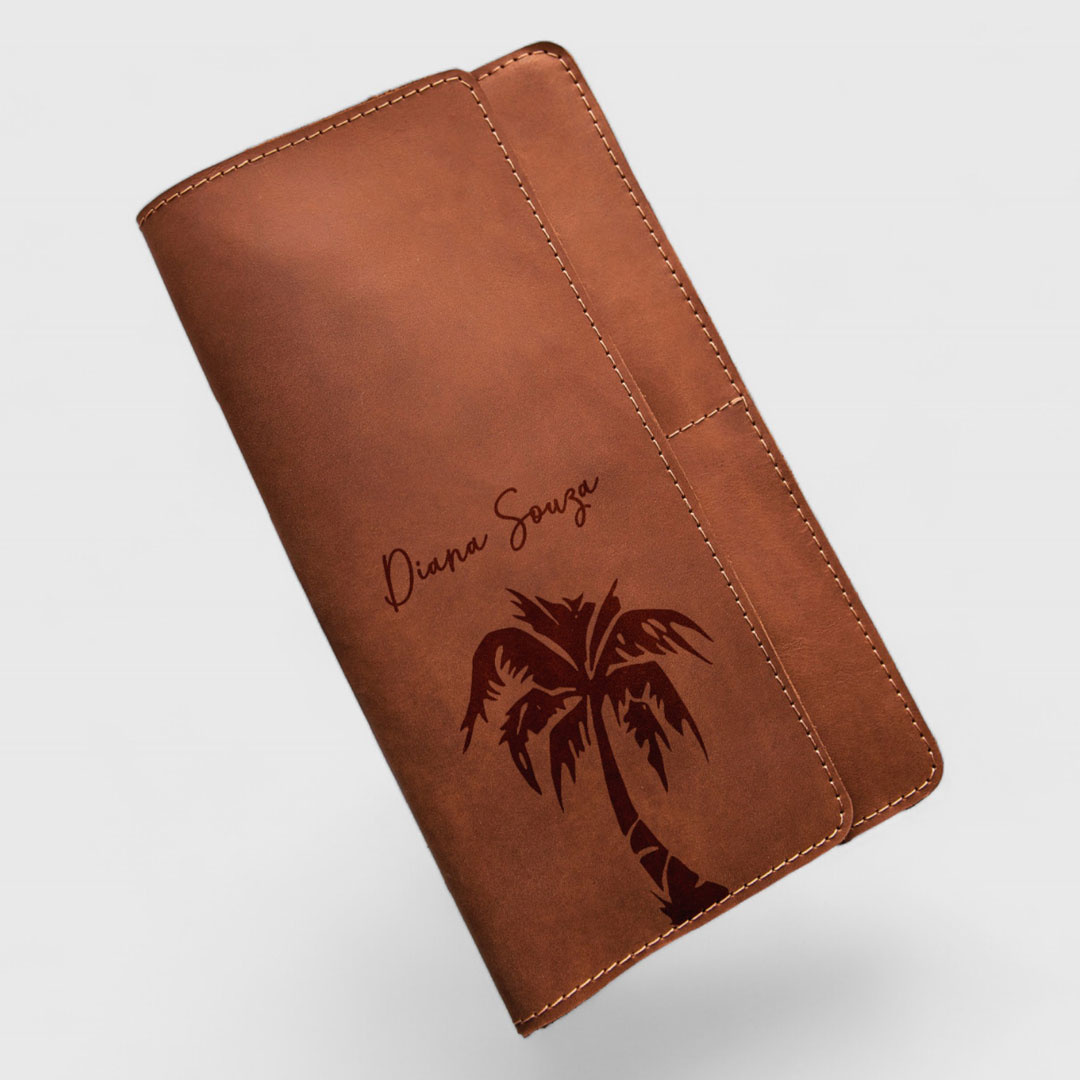

- Fashion and Textiles: Detailed cutting and personalization applications on fabric and leather.

- Electronics and Automotive: Precision cutting and functional markings on small, complex components.

Laser cutting and marking machines provide a process that meets the expectations of modern industry by enabling speed, quality, and cost control in production. Configurable to different needs—from industrial lines to workshop use—these systems simplify operations with their user-friendly structure. With advanced laser technology, they increase workforce efficiency and ensure a consistent quality standard.

Production You Can Trust

Venox laser cutting and marking systems support your production processes with high safety standards. While strengthening traceability with clear and permanent markings, they elevate operational safety to the highest level with protective enclosures and safety measures.